Date:2024-04-02

Introduction

As the importance of sustainability continues to grow, ink manufacturers are developing new systems to improve recycling and compostability, and packaging inks have been one of the strongest growth areas in recent years. New technologies that ease concerns about recycling and food migration have been bright spots, and overall, the ink market for the packaging industry continues to grow globally.

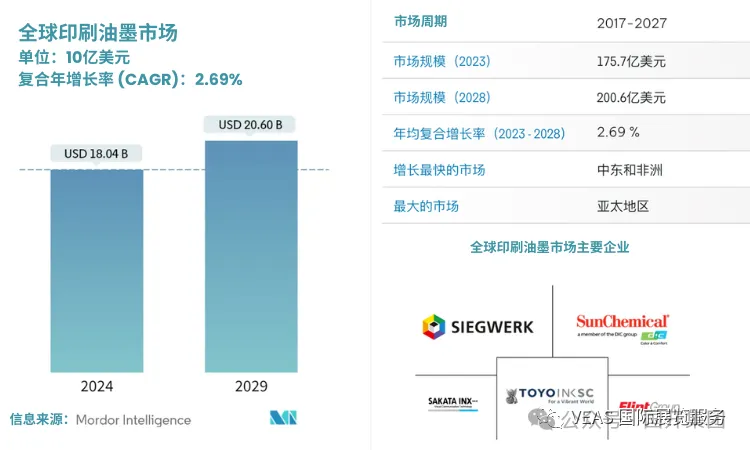

Mordor Intelligence recently released a global ink market report, which details key factors such as printing ink product types, process technologies, application areas, and regional markets, and forecasts the development of the global ink printing market from 2023 to 2028.

The report predicts that the printing ink market will achieve significant growth in the future, and the market size will grow from $17.57 billion in 2023 to $20.16 billion in 2028. The compound annual growth rate (CAGR) during the forecast period is 2.69%. However, the market has experienced many fluctuations in the wake of the COVID-19 outbreak in 2020.

01 water, solvent and UV ink for packaging

The sustainability advantages of using solvent-based, water-based and UV types are discussed. Buddy Graves, Sun Chemical Solvents product Manager, said: "While there will be no major changes to ink technology in 2023, the increased focus on the Sustainable Development Goals and their associated timelines could drive a shift in the industry in the near future."

Flint Group Aldred said that due to the good recycling properties of recycled fibers, Flint Group is moving away from rigid materials to more sustainable fiber-based substrates. "Due to the high ratio of products to packaging, lighter weight forms, packaging features and attractive design of shelves, the flexible packaging market remains resilient and translates into continued growth. In the UV space, we continue to see resilient performance from UV flexo printing and UV leds, especially in the label market."

02 Changes in the nature of packaging

Flint's Aldred says packaging is driven by a number of drivers - from glass and wood to paper and film. "The transformation of the packaging market can be attributed to sustainability, packaging functionality, food waste reduction, regulatory compliance, and branding. For example, ten years ago, consumers bought a can of hard pet food. Today, the food is sold in recyclable film bags that are easy to open and close, with a brand logo, which may appeal to consumers keen to buy environmentally friendly packaging products."

One change is that printers' customers are asking ink manufacturers to meet with brand owners to discuss sustainability and regulatory issues. Takano of Toyo Ink said: "We work closely with brand owners to understand their needs and optimize solutions for them in terms of barrier performance, sustainability and regulatory compliance. In this way, brand owners are a key driver in promoting sustainability and food safety standards. Overall, the EU is at the forefront of packaging regulatory development and its policies have had a trickle-down effect on Asia and the rest of the world."

Aldred said Flint Group's global team works with clients on a daily basis on sustainability and regulation-related topics, and has employees who are focused on these two important topics: local and global. "The customer is focused on reducing range 3 emissions, which is related to the recyclability of packaging, so the development of products such as Flint Group's Evolution range of substrates and finishes is crucial."

03 The latest development of packaging inks

As the importance of sustainability continues to grow, ink manufacturers are developing new systems to improve recycling and compostability.

"Toyo Ink's portfolio of functional coatings offers additional features such as oil resistance, water resistance, heat resistance, UV protection and barrier properties," Takano said. Takano continued, "New products in the barrier coatings family are thermal sealants and OP polish, which can replace or reduce film layers in paper or flexible packaging structures while keeping the paper or plastic film in the recycling stream. These coatings can also replace aluminum or foil as barrier layers in flexible packaging structures."

Aldred said Flint Group's Evolution range, which is designed to deink (base coat) or fix ink (varnish) label substrates during recycling, is gaining global exposure. "These products are designed to support a smooth recycling process and promote a circular economy, and for paper and board printers, Flint Group offers bio-based water-based inks and coatings that enable flexible packaging printers to streamline ink management and provide them with high quality, consistency and cost savings." These versatile nitrocellulose concentrates enable processors to mix polyurethane (PU) and nitrocellulose (NC) inks from the same series of concentrates without the need to duplicate inventory. Our recently introduced Novasens P670 PRIME for single-sheet packaging enables printers to print longer and faster on ever-changing board grades with improved paper release, consistent ink transfer, and high intensity color and vitality."

In the post-pandemic era, the food and beverage industry has taken the lead in starting to recover and is showing positive signs of recovery. The short-term growth of the ink market is driven by increased demand from the digital printing industry and packaging sector. On the contrary, the decline of traditional commercial printing and stringent regulations may pose obstacles to the growth of the ink market.

China plays a key role in the Asia-Pacific printing ink market. With the rapid growth of the construction industry and high demand for interior decoration, China, as the world's largest manufacturing and export economy, has created favorable conditions for the development of the printing ink market.

Overall, the printing ink market is showing good prospects due to the increased demand from the packaging and digital printing industries. On the back of growth in related industries such as food and beverage and textiles, the printing inks market is expected to achieve significant growth in the coming years.

Disclaimer: This article is reproduced on our website to provide readers with more news information. The content does not constitute investment, consumption advice, only for readers' reference

Location >>

Location >>