Date:2024-03-29

We all know that digital printing and ink segment is growing, albeit faster in certain markets. Industry leaders say that as the technology improves, growth will continue across almost all printing segments.

While Phil Jackman, global product manager, Digital, Sun Chemical, pointed out that inkjet today is very capable and can surpass image quality and productivity requirements for most markets, the growth and conversion rate can be slow.

“This is mostly because mainstream print markets are served by highly evolved and capable analog presses that won’t disappear overnight,” Jackman said. “For example, it took around 10 years of them being available for the sales of new digital label presses to overtake analog new label press sales.

“There are some perceived barriers to adoption of inkjet including capital cost and unknown reliability, but the technology and performance will continue to progress,” Jackman noted.

“However, adoption of digital printing is not just about the printing technology. The changing customer requirements will accelerate the need for shorter run lengths and a faster turnaround of jobs. Often, a different business model and changes to workflow both in pre-press and post-print may all be required to be adopted to fully maximize the capability of the digital print technology.”

Mark Goodearl, senior ink product manager for EFI, observed that in some markets like display graphics, there is great awareness of digital printing.

“And, much of the activity in that market comes in the form of businesses that already do digital printing replacing their devices with newer, faster printers,” Goodearl continued.

“Manufacturers such as EFI have to remain laser-focused on the value digital creates for our customers to ensure continued growth. And we have to be innovative. This is especially true when looking to newer industrial markets such as flooring and wallcoverings. Digital has tremendous potential in those markets because of inkjet’s ability to drive greater flexibility, creativity and efficiency. ”

"The standard challenges still remain; make the printers faster, cheaper, and more capable of handling a larger variety of materials with quick changeover,” Jay Larsen, GM and director of R&D for INX International's digital hardware division, said. “We believe the continued progress of food safety will allow more application of digital UV printing into the food, beverage and pharma/medical markets."

“Regulatory changes are going to greatly affect how digital printing can move forward in some print spaces,” Josh Boivin, inkjet sales for Wikoff Color Corporation, said. “This greatly affects food packaging, toy printing, consumer goods, and foreign markets.”

Gabriela Kim, global marketing manager – DuPont Artistri Digital Inks, noted that there are still some technical challenges that digital printing will have to overcome when it comes to the longer runs.

“Analog printing is still a very productive method for large and fast print runs,” added Kim. “That still is a challenge for digital printing.”

Randy Vandagriff, SVP, Digital Print, Eastman Kodak Company, said that there needs to be greater acknowledgement that digital can complement offset.

“A shop, large or small, can benefit from having an inkjet printer beside its offset press,” said Vandagriff. “It lessens the load and stress when running the right-sized job on the right press. Operational effectiveness can greatly affect a company’s bottom line, especially with a three-shift operating schedule.

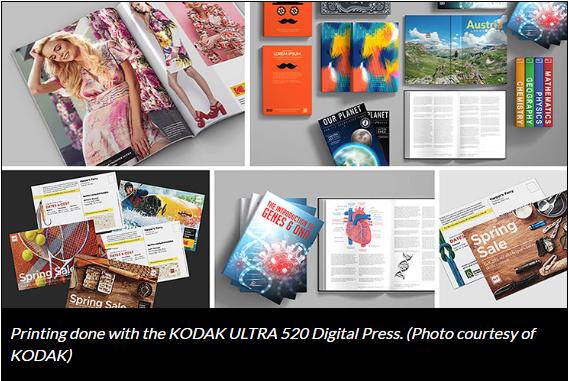

“Getting started in digital can be perceived as cost-prohibitive,” Vandagriff continued. “With the right volume, ink coverage, and press, printers can strengthen their bottom line and potentially grow their business by offering a digital press that can accommodate new and different applications. Instead of producing high-volume jobs, digital printing is primarily about efficiently handling smaller, but a much larger number of jobs. Businesses need to adapt their operational infrastructure to this change. This means that, in addition to digital printing equipment, they also need to invest in powerful workflow automation software capable of meeting the demands of such a job structure. Reproducing color and quality has been a struggle however, continuous technological advancements, such as Kodak ULTRASTREAM, bridge the gap with offset.”

Source: https://www.inkworldmagazine.com/contents/view_online-exclusives/2023-05-10/despite-growth-there-are-challenges-ahead-for-digital-printing/

Location >>

Location >>