Date:2025-10-23

On October 16, as a core supporting event of Asia Ink Expo 2025, the Asia Ink Industry Development Conference was successfully held at the conference Hall 2, Guangzhou Aerotropolise Expo Center. Focusing on green transformation and technology empowerment, the conference invited 10 policy experts, academic scholars, and corporate technical representatives to share insights—addressing both industry compliance challenges and introducing innovative application solutions, which were highly praised by attendees for their practicality.

Ⅰ.Policy Interpretation + Bio-based Innovation: Dual Engines Driving Green Transformation

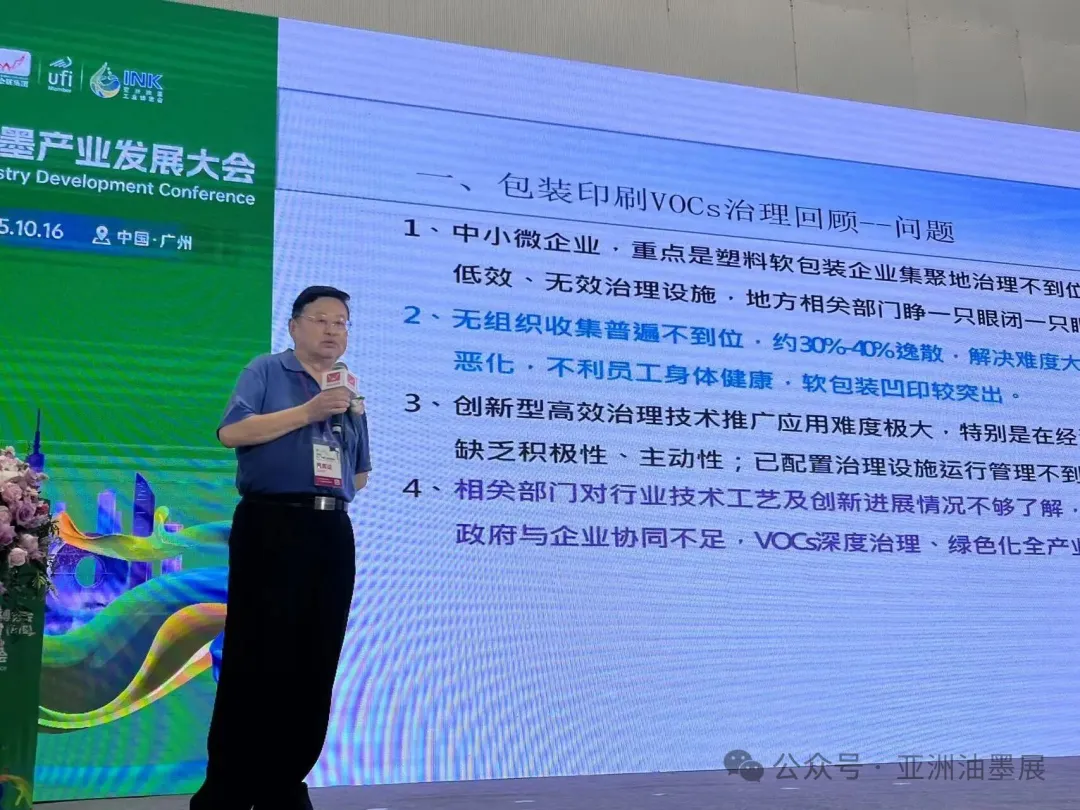

The morning sessions focused on technical specifics, while the afternoon program expanded to cover policies, materials, and cutting-edge applications.The second half of the conference featured consecutive sessions on policy and material innovation, delivering dual support—"direction + pathway"—for the industry's green development.Jianjun Li, advisor to the VOCs Governance Committee of China Printing and Equipment Industries Association, opened with a presentation titled "Source Reduction Alternatives for Packaging Printing VOCs and Policy Directions," directly addressing industry pain points: "SME packaging manufacturers predominantly rely on inefficient treatment systems, with fugitive emissions accounting for 30%-40% of total VOCs. Gravure water-based ink application is key to source reduction." His integrated solution—"water-based printing + energy-efficient drying + ethanol recovery"—captivated attendees. By achieving over 85% waste heat recovery efficiency and 90% ethanol purity, this approach enables a single 10-color press to yield annual energy savings of 380,000-1.15 million RMB while reducing VOCs by 80%, truly achieving synergistic "emission reduction, decarbonization, and cost savings." Li also clarified China's 15th Five-Year Plan policy orientation: inefficient treatment systems will be phased out mandatorily, while low-VOCs material applications will receive strengthened support, drawing a clear compliance baseline for corporate transformation.

Following this presentation, Professor Wenxun Guo from the College of Materials Science and Engineering at Hunan University delivered a presentation titled "Application of Saccharides in Water-based UV Inks, Coatings, and Varnishes." He proposed using glucose syrup and whole sucrose syrup as bio-based raw materials in combination with water-based UV resins, achieving near-zero VOC emissions while imparting antimicrobial and antiviral properties to the inks. The specialized resin developed by his team demonstrated a sterilization rate exceeding 99.99% against E. coli and Staphylococcus aureus, making it suitable for sensitive applications such as children's products and medical packaging. On-site application examples further highlighted the innovation's value: textbook covers and wood varnish samples made with this material achieved a gloss level of over 102 degrees, effectively balancing environmental sustainability with aesthetic quality and opening a new pathway of "bio-based + functionalization" for the ink industry.

Ⅱ.Digital Inks Break New Ground, Unlocking Novel Possibilities for Industrial Applications

While discussions on green transformation focused on "industry responsibility," the session on "Innovative Applications of Digital Inks" presented by Lihai Feng, Digital Technology Service Engineer at MARABU China, revealed new "market growth potential" in the ink industry for attendees.

Lihai Feng challenged conventional perceptions with a series of industrial-grade case studies: The Ultra Jet DUV-C series UV inks can achieve 3mm thick embossed printing, enabling direct printing of three-dimensional brand logos on wine bottles and even adapting to aircraft fuselage applications. For the automotive sector, his "digital + screen printing" hybrid solution allows precise pattern printing on PC films, which—when overlayed with silk screen-printed layers—had passed the rigorous forming and delamination tests, meeting the demands of IML (In-Mold Labeling) processes. "I previously thought digital inks were only suitable for small-batch customization, but now I see their applicability in high-end manufacturing sectors like automotive and aerospace," sighed a packaging printing company executive among the audience. Feng also highlighted that these digital inks offer precise compatibility with various printhead models while balancing adhesion and scratch resistance, providing technical support for ink manufacturers to expand their business boundaries.

Ⅲ.The tightly-packed agenda delivered tangible outcomes, effectively building bridges for industrial collaboration.

The coffee breaks became "golden hours" for participants to engage deeply with speakers—clusters of attendees gathered around Jianjun Li to discuss regional policy variations, consulted Wenxun Guo on cost adaptability of bio-based materials, and explored equipment compatibility for digital inks with Lihai Feng, maintaining vibrant discussions throughout the venue.

The value of this conference extends far beyond mere "information dissemination": it created alignment points where regulatory requirements meet corporate needs, and where laboratory innovations in materials connect with production line realities. As one participating ink manufacturer noted, "I used to view green transformation as merely a cost for reducing pollution. Today, I realized that policies harbor opportunities and innovative technologies hold market potential. This conference served as the bridge that connected them for us."

As the conference concluded, participants departed with clarified policy directions, practical technical solutions, and valuable collaboration opportunities. The core philosophy of "green innovation and technological breakthrough" championed by this event is now emerging as a fresh driving force propelling the high-quality development of Asia's ink industry.

Location >>

Location >>