Date:2025-09-22

Guangzhou Ledi New Material Technology Co., Ltd. has introduced an innovative UV LED ink series tailored to the practical needs of the printing industry. Utilizing ultraviolet rapid-curing technology, this product line significantly enhances production efficiency while substantially reducing energy consumption. Designed for printing on various material surfaces, it offers excellent adhesion and weather resistance, meeting industrial-grade application requirements. The environmentally friendly formulation contains no harmful solvents, effectively improving the working environment.

As a national high-tech enterprise, Ledi provides a comprehensive technical support system and offers formula customization and equipment adaptation based on client needs, supporting businesses in transitioning toward greener and more efficient production methods.

In today’s highly competitive manufacturing industry, every improvement in production efficiency and cost control at each process stage directly impacts a company’s competitiveness. For the printing sector, traditional methods often suffer from high energy consumption, slow drying times, and significant pollution issues. The emergence of UV LED ink, however, is driving industry transformation through technological innovation.

As a specialized solution provider in the field of functional inks, Guangzhou Ledi New Material Technology Co., Ltd. leverages its independently developed UV LED ink product series to help companies transition from high-energy-consumption models to green and intelligent manufacturing—setting a new benchmark for efficient production.

I. Breaking with Tradition: The Technological Innovation of UV LED Inks

Compared to traditional solvent-based inks, Ledy UV LED ink stands out with its signature "cure-on-demand" feature. By leveraging ultraviolet curing technology combined with high-precision LED irradiation equipment, the ink achieves near-instantaneous solidification, replacing time-consuming natural drying or high-temperature baking processes. Third-party tests confirm that production lines using this ink experience a 65% reduction in per-batch product delivery cycles and significantly improved equipment utilization rates. Enterprises can achieve continuous production without investing in large-scale drying facilities, effectively optimizing floor space usage.

Notably, its exceptional energy-saving performance sets a new standard. While traditional infrared drying systems require sustained high energy consumption to maintain elevated temperatures, Ledy UV LED ink triggers the curing reaction with low-power LED light sources. Actual measurements show that using this ink reduces electricity consumption by approximately 80% for the same output volume, substantially lowering factory operating costs. This on-demand energy use model aligns with national dual-carbon policy goals while providing enterprises with a practical pathway to build low-carbon supply chains.

II. Comprehensive Performance: Meeting Diverse Industrial Needs

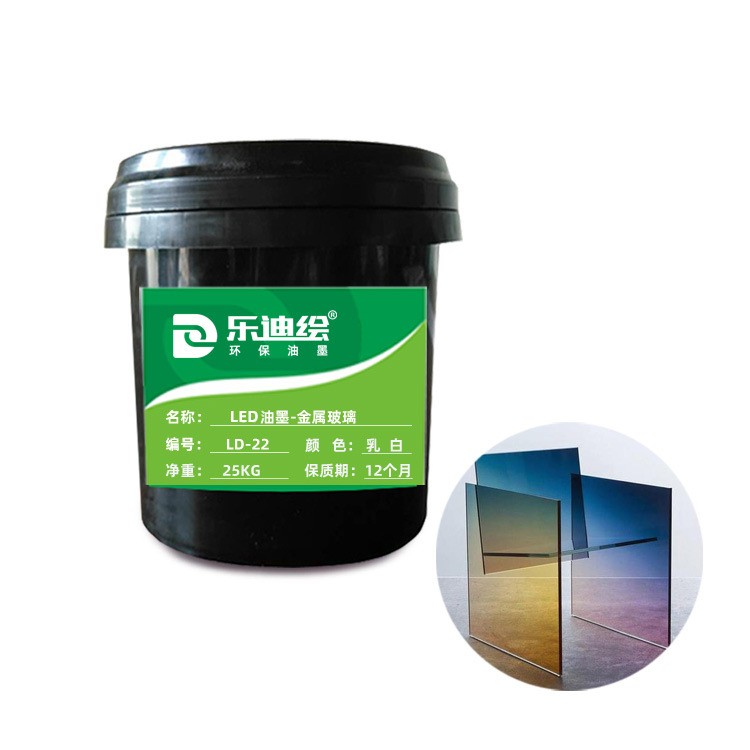

Ledi UV LED ink is not merely a fast-drying product but excels in adhesion strength, weather resistance, color accuracy, and more. Through optimized molecular design, the ink forms stable cross-linked structures on various substrates such as metal, glass, ceramic, and plastic, ensuring exceptional wear resistance and chemical corrosion protection. A weather-resistant version developed for outdoor environments, validated by xenon lamp aging tests, maintains color integrity for over five years, making it ideal for long-term outdoor applications like advertising billboards and electronic display borders.

In terms of color performance, the R&D team employs nano-scale pigment dispersion technology and spectral matching techniques, enhancing color saturation by 30% compared to conventional products. Even fine text achieves sharp, clear edges. Additionally, specially developed transparent conductive ink opens new possibilities for flexible electronics and touch panels, expanding the application scope of UV curing technology.

III. Safety and Reliability: Ensuring a Healthy Production Environment

Volatile organic compound (VOC) emissions have long been a persistent environmental challenge in the printing industry. Ledi UV LED ink strictly complies with EU REACH regulations and contains no harmful solvents such as benzene or ketones in its formulation. Additionally, it requires no diluents during production. When integrated with a closed ink supply system, it effectively minimizes odor dispersion in the workshop, significantly improving overall air quality.

Tested by SGS, the ink demonstrates a skin irritation index below 0.5, meeting the de facto non-toxic standard. This provides reliable health protection for operators, ensuring both workplace safety and environmental compliance.

IV. Broad Applications: Enabling Innovative Practices Across Industries

From digital printing on packaging materials to surface treatment of automotive parts, from precision printing on circuit boards to medical device labeling, Ledi UV LED ink has penetrated diverse manufacturing sectors. For instance, a home appliance manufacturer reported that after adopting this ink in their air conditioner panel production line, the curing time for a process that previously took 48 hours was reduced to under 2 minutes, while the product defect rate dropped to below 0.1%.

In the cosmetics packaging industry, leveraging its food-grade safety certification, the ink has enabled the creation of visually striking best-selling products with enhanced aesthetic appeal and compliance.

Location >>

Location >>